Government

De-risking Cell Therapy New Product Introduction

Sponsored content brought to you by In 2023, the number of FDA-approved cell and gene therapies is poised to increase by more than 50%. As the number of…

Sponsored content brought to you by

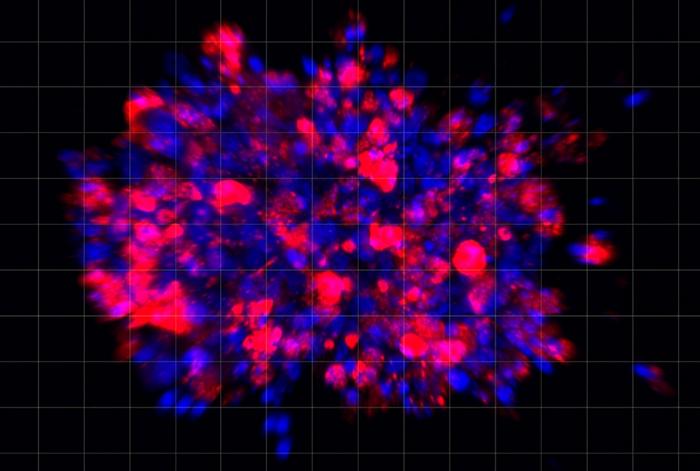

In 2023, the number of FDA-approved cell and gene therapies is poised to increase by more than 50%. As the number of commercially available cell therapies increases, the industry must evolve in many ways. As Matthew Hewitt, PhD, vice president, technical officer CGT & Biologics at Charles River Laboratories, said at the 2023 CAR-TCR conference in Boston, “Ultimately, this is all about the patients for us.” Serving as many patients as possible in the most effective ways, however, depends on optimized approaches to reducing the inherent risk in introducing a new cell therapy.

The complexity of cell therapies creates much of that risk. As Hewitt put it: “In the advanced therapeutic space, we’re using biology to modulate biology.” To streamline and reduce the risk of new product introduction (NPI), Charles River has curated a complete solution from cell sourcing through GMP-manufacturing for advanced therapies. This solution includes a scalable and robust technology transfer framework.

Making the most of this framework depends on a thorough understanding of the best approaches to each step. For example, innovation takes place during development, and implementation underlies GMP. As Hewitt says: “The brains think to develop; the hands do to execute.”

Overcoming obstacles

To provide patients with more cell-therapy options, they first need to get to and through clinical trials. “Everybody wants to get to the clinic quickly,” Hewitt says.

To make the move more efficiently to the clinic and then to the market, Hewitt pointed out three key elements: adhering to timelines; clearly documenting GMP processes; and performing phase-appropriate quality assurance (QA).

Still, moving to commercial-scale manufacturing creates several industry challenges, often involving testing and analytics. Here, Charles River takes several approaches to improvement. “We’re continuing to work on better models on the in vivo side as well as seeing what we can leverage on the in vitro side to not only further reduce animal use but also hopefully improve the translatability to the clinic,” Hewitt explains.

In fact, Charles River’s NPI framework optimizes the entire NPI process, which includes documentation generation, assay qualification, and GMP-transfer activities. Currently, that process requires about 10.5 months however running processes in parallel where possible and creating teams that integrate information from various steps and processes enables significant reductions.

Focus on all phases

Introducing a new product program with a CDMO includes three phases: capture, which includes the contract and the proposed development process; planning, which is the layout of the activities required from start to finish; and execution—basically completing the work.

“Ultimately, NPI is about execution, but if you don’t have the proper capture in terms of accurately knowing what we’re taking in and you don’t have the proper planning on activities then it’s very hard to execute in an organized fashion,” Hewitt says. “We put an emphasis on all three of these to get into GMP more quickly.”

Plus, Charles River is continually improving its processes. With documentation, for example, the company is moving from paper to electronic batch records. “If we’re going to move to tens of thousands of doses per year, there’s no way to review that with paper,” Hewitt notes.

The CDMO understands the GMP pathway in exquisite detail, however Hewitt explains that “We have to take the nuance out of the process and put it into something that everybody can follow—an informed set of directions.”

Working with regulatory agencies, Charles River also hopes to transform the future of cell-therapy manufacturing. “A lot of us want to do parallel manufacturing of therapies—not only of different patients but of different therapies,” Hewitt says. “We need to get more efficient with manufacturing capacity to increase doses to expected levels.” That brings him back to where he started—it’s all about the patients.

Learn more from Dr. Matthew Hewitt in this on-demand presentation recording https://bit.ly/3Z4QmiF

The post De-risking Cell Therapy New Product Introduction appeared first on GEN – Genetic Engineering and Biotechnology News.

Here Are the Champions! Our Top Performing Stories in 2023

It has been quite a year – not just for the psychedelic industry, but also for humanity as a whole. Volatile might not be the most elegant word for it,…

AI can already diagnose depression better than a doctor and tell you which treatment is best

Artificial intelligence (AI) shows great promise in revolutionizing the diagnosis and treatment of depression, offering more accurate diagnoses and predicting…

Scientists use organoid model to identify potential new pancreatic cancer treatment

A drug screening system that models cancers using lab-grown tissues called organoids has helped uncover a promising target for future pancreatic cancer…