Recently, a team led by Prof. ZHANG Shiwu from the University of Science and Technology of China (USTC) and their collaborators from UK and Australia developed a new electro-mechano responsive elastomer that autonomously adjust stiffness, conductivity and strain sensitivity in response to changes in external mechanical loads and electrical signals. Their research was published in Science Advances.

Nowadays, more and more application scenarios like soft robotics and medical surgical equipment call for self-tunable intelligent materials. A widely adopted solution is composite material composed of low melting point alloy and elastic polymer. However, such material is unable to automatically respond to external changes and can only switch between conductive and insulating states.

To fill this gap, the team developed a Field’s metal-filled hybrid elastomer (FMHE) composed of nickel (Ni) microparticles, low melting point Field’s metal (FM) and polymer matrix. The multi-filler conductive network formed by spiked Ni particles and FM particles enables the conductivity of the FMHE to grow exponentially under different mechanical loads such as compression, twist and bend. When FMHE is heated to 60℃ and above, the FM particles within are melted. Melted FM droplets can’t form conductive paths like solid particles, but deforms with polymer matrix under load, which significantly reduces the elastic modulus, conductivity and strain sensitivity. Since the material’s electrical resistance decrease as it deforms, self-tunable conductivity and stiffness can be achieved by heating and applying certain pressure on FMHE.

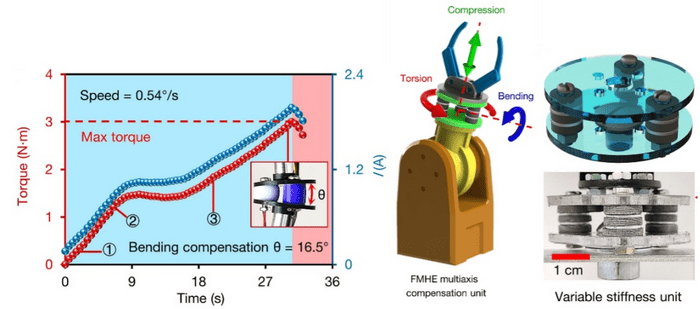

Combining the variable resistance and stiffness properties, the research team developed a self-triggered multiaxis compliance compensator for robotic manipulators, which can compensate for positional and angular errors through its deformation, avoiding damage to equipment in complex operating environments. The team’s FMHE-based device showed greater compensation capability than that of current commercial systems (bending angle of 16.5° over 1.1°). Furthermore, the team developed a resettable current-liming fuse based on FMHE. When reaching the fusing current, the resistance of the fuse can increase 1000 times in 0.1 seconds to cut off the circuit and reset in 10 seconds.

The intelligent materials developed by the team enabled synergistic utilization of tunable electrical and mechanical properties, showing great potential in its application to the next generation soft robotics and electronic devices.

Journal

Science Advances

DOI

10.1126/sciadv.adf1141

Article Title

Electro-mechano responsive elastomers with self-tunable conductivity and stiffness

Article Publication Date

25-Jan-2023